Oversized cylinder bores waste up to 40% more compressed air than necessary, dramatically increasing energy costs and reducing system efficiency in manufacturing facilities already struggling with rising utility expenses. Optimal cylinder bore size is determined by calculating the minimum force requirements, adding a 25-30% safety factor, then selecting the smallest bore that meets pressure and speed specifications while considering air consumption rates and energy efficiency targets. Just yesterday, I worked with Jennifer, a plant engineer from Ohio, whose facility was experiencing skyrocketing compressed air costs because their previous supplier had oversized every rodless cylinder1 by 50%, leading to massive energy waste across their automated production lines. ⚡

Table of Contents

- What Factors Determine the Minimum Required Cylinder Bore Size?

- How Do You Calculate Air Consumption and Energy Costs for Different Bore Sizes?

- Why Do Bepto Cylinders Deliver Maximum Energy Efficiency Across All Bore Sizes?

What Factors Determine the Minimum Required Cylinder Bore Size?

Understanding the key variables that influence bore size selection ensures optimal performance while minimizing energy consumption and operational costs.

Cylinder bore size is determined by load force requirements, operating pressure availability, desired speed performance, and safety factors, with the optimal selection balancing adequate force output against air consumption efficiency to minimize compressed air costs while maintaining reliable operation.

Cylinder Theoretical Force Calculator

Calculate the theoretical push and pull force of a cylinder

Input Parameters

Theoretical Force

Force Calculation Fundamentals

The primary factor in bore size selection is the theoretical force2 requirement based on your application’s load conditions.

Basic Force Formula:

- Force (N) = Pressure (bar) × Area (cm²) × 10

- Area = π × (Bore Diameter/2)²

- Required Bore = √(Force Required / (Pressure × π × 2.5))

Load Analysis Components:

- Static load: Weight of components being moved

- Dynamic load: Acceleration and deceleration forces

- Friction load3: Bearing and guide resistance

- External forces: Process forces, wind resistance, etc.

Pressure and Speed Considerations

Available system pressure directly impacts the minimum bore size needed to generate required force output.

| System Pressure | 50mm Bore Force | 63mm Bore Force | 80mm Bore Force | 100mm Bore Force |

|---|---|---|---|---|

| 4 bar | 785N | 1,247N | 2,011N | 3,142N |

| 6 bar | 1,178N | 1,870N | 3,016N | 4,712N |

| 8 bar | 1,571N | 2,494N | 4,021N | 6,283N |

| 10 bar | 1,963N | 3,117N | 5,027N | 7,854N |

Safety Factor Application

Proper safety factors ensure reliable operation while preventing oversizing that wastes energy.

Recommended Safety Factors:

- Standard applications: 25-30%

- Critical applications: 35-50%

- Variable load conditions: 40-60%

- High-speed applications: 30-40%

Jennifer’s case was a perfect example of oversizing consequences. Her previous supplier had applied 100% safety factors “to be safe,” resulting in 63mm bores where 40mm would have been adequate. We recalculated her requirements and downsized appropriately, cutting her air consumption by 35%! 💡

How Do You Calculate Air Consumption and Energy Costs for Different Bore Sizes?

Accurate air consumption calculations reveal the true cost impact of bore size decisions and enable data-driven optimization for maximum energy efficiency.

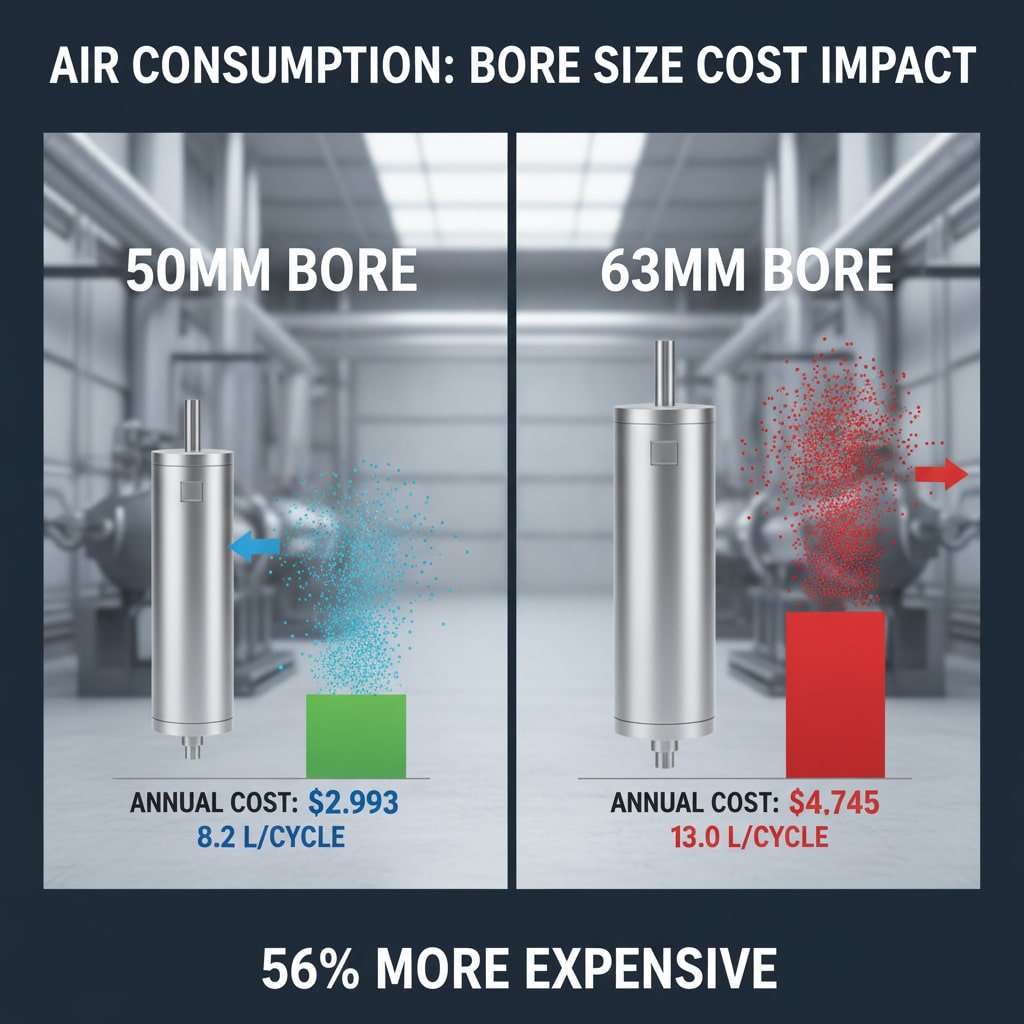

Air consumption increases exponentially with bore size, with a 63mm cylinder consuming 56% more air than a 50mm cylinder per cycle, making precise bore sizing critical for minimizing compressed air costs4 that can represent 20-30% of total facility energy expenses.

Air Consumption Calculation Methods

Standard Formula:

- Air Volume (L/cycle) = Bore Area (cm²) × Stroke (cm) × Pressure (bar) × 1.4

- Daily Consumption = Volume per cycle × Cycles per day

- Annual Cost = Daily consumption × 365 × Cost per m³

Practical Example:

- 50mm bore, 500mm stroke, 6 bar, 1000 cycles/day

- Volume per cycle = 19.6 × 50 × 6 × 1.4 = 8,232L = 8.23m³

- Daily consumption = 8.23m³

- Annual consumption = 3,004m³

Energy Cost Comparison Analysis

Bore Size Impact on Operating Costs:

| Bore Size | Air per Cycle | Daily Usage | Annual Cost* |

|---|---|---|---|

| 40mm | 5.3 L | 5.3 m³ | $1,934 |

| 50mm | 8.2 L | 8.2 m³ | $2,993 |

| 63mm | 13.0 L | 13.0 m³ | $4,745 |

| 80mm | 21.1 L | 21.1 m³ | $7,702 |

*Based on $0.65/m³ compressed air cost, 1000 cycles/day

Optimization Strategies

Right-Sizing Approach:

- Calculate minimum theoretical force

- Apply appropriate safety factor (25-30%)

- Select smallest bore meeting requirements

- Verify speed and acceleration capabilities

- Consider future load changes

Energy Efficiency Factors:

- Lower operating pressure when possible

- Implement pressure regulation

- Use flow control for speed optimization

- Consider dual-pressure systems for varying loads

Michael, a maintenance manager from Texas, discovered his facility was spending $45,000 annually on excess compressed air due to oversized cylinders. After implementing our bore optimization recommendations, he reduced air consumption by 28% and saved over $12,000 per year! 🎯

Why Do Bepto Cylinders Deliver Maximum Energy Efficiency Across All Bore Sizes?

Our precision engineering and advanced design features ensure optimal energy efficiency regardless of bore size, helping customers minimize operating costs while maintaining superior performance.

Bepto rodless cylinders feature optimized internal geometries, low-friction sealing systems5, and precision manufacturing that reduces air consumption by 15-20% compared to standard cylinders while delivering superior force output and positioning accuracy across all bore sizes from 32mm to 100mm.

Advanced Efficiency Features

Optimized Internal Design:

- Streamlined air passages minimize pressure drops

- Precision-machined surfaces reduce turbulence

- Optimized port sizing for maximum flow efficiency

- Advanced cushioning systems reduce air waste

Low-Friction Sealing Technology:

- Premium seal materials reduce operating friction

- Optimized seal geometries minimize drag

- Self-lubricating seal compounds

- Reduced breakaway force requirements

Performance Validation Data

| Efficiency Metric | Bepto Cylinders | Standard Cylinders | Improvement |

|---|---|---|---|

| Air Consumption | 15% lower | Baseline | 15% savings |

| Friction Force | 25% lower | Baseline | 25% reduction |

| Pressure Drop | 20% lower | Baseline | 20% improvement |

| Energy Efficiency | 18% better | Baseline | 18% savings |

Comprehensive Sizing Support

Engineering Services:

- Free bore size optimization analysis

- Air consumption calculations

- Energy cost projections

- Application-specific recommendations

Technical Tools:

- Online bore sizing calculator

- Energy efficiency worksheets

- Comparative cost analysis

- Performance prediction models

Quality Assurance:

- 100% efficiency testing before shipment

- Pressure drop verification

- Friction force measurement

- Long-term performance validation

Our energy-efficient design has helped customers reduce compressed air costs by an average of 22% while improving system performance. We don’t just supply cylinders – we engineer complete energy optimization solutions that deliver measurable ROI! 🚀

Conclusion

Proper cylinder bore sizing balances force requirements with energy efficiency, enabling significant cost savings through optimized air consumption while maintaining reliable performance.

FAQs About Cylinder Bore Size and Energy Efficiency

Q: What’s the most common mistake in cylinder bore sizing?

Oversizing cylinders with excessive safety factors is the most common error, often resulting in 30-50% higher air consumption than necessary while providing no performance benefit.

Q: How much can proper bore sizing reduce my compressed air costs?

Optimal bore sizing typically reduces air consumption by 20-35% compared to oversized cylinders, translating to thousands of dollars in annual energy savings for typical manufacturing facilities.

Q: Should I always choose the smallest possible bore size?

No, the bore must provide adequate force with appropriate safety factors. The goal is finding the smallest bore that reliably meets all performance requirements including force, speed, and acceleration.

Q: How do I account for varying load conditions in bore sizing?

Size the cylinder for maximum expected load conditions with a 25-30% safety factor, or consider dual-pressure systems that can operate at lower pressure for lighter loads.

Q: Why should I choose Bepto cylinders for energy-efficient applications?

Bepto cylinders deliver 15-20% lower air consumption through advanced internal design and low-friction sealing technology, backed by comprehensive sizing support and energy optimization expertise.

-

Learn more about the design and common applications of rodless pneumatic cylinders. ↩

-

Understand the detailed engineering principles behind calculating theoretical force for pneumatic actuators. ↩

-

Review the fundamental formulas for calculating friction load in linear motion systems. ↩

-

Explore an in-depth analysis of how compressed air costs are calculated in industrial facilities. ↩

-

Discover the materials and engineering behind advanced low-friction sealing systems in pneumatics. ↩