Standard pneumatic cylinders operate at uncontrolled speeds, creating inconsistent cycle times and poor product quality in precision applications. Basic speed controls cause jerky motion and pressure spikes that damage equipment and reduce reliability. Meter-out circuits use precision flow control valves on the exhaust side to create back-pressure1 that smoothly regulates cylinder speed throughout the entire stroke – providing consistent, adjustable motion control with excellent load handling and superior positioning accuracy for demanding industrial applications. Two days ago, I helped Thomas, a production supervisor from Texas, whose assembly line had 15% cycle time variation causing quality issues. Our Bepto meter-out circuit design reduced variation to under 2% while improving product consistency by 40%. ⚙️

Table of Contents

- Why Are Meter-Out Circuits Superior to Meter-In Speed Control Methods?

- How Do You Design Effective Meter-Out Circuits for Different Applications?

- What Are the Key Performance Benefits of Proper Meter-Out Implementation?

- Why Should You Choose Bepto’s Engineered Speed Control Solutions?

Why Are Meter-Out Circuits Superior to Meter-In Speed Control Methods?

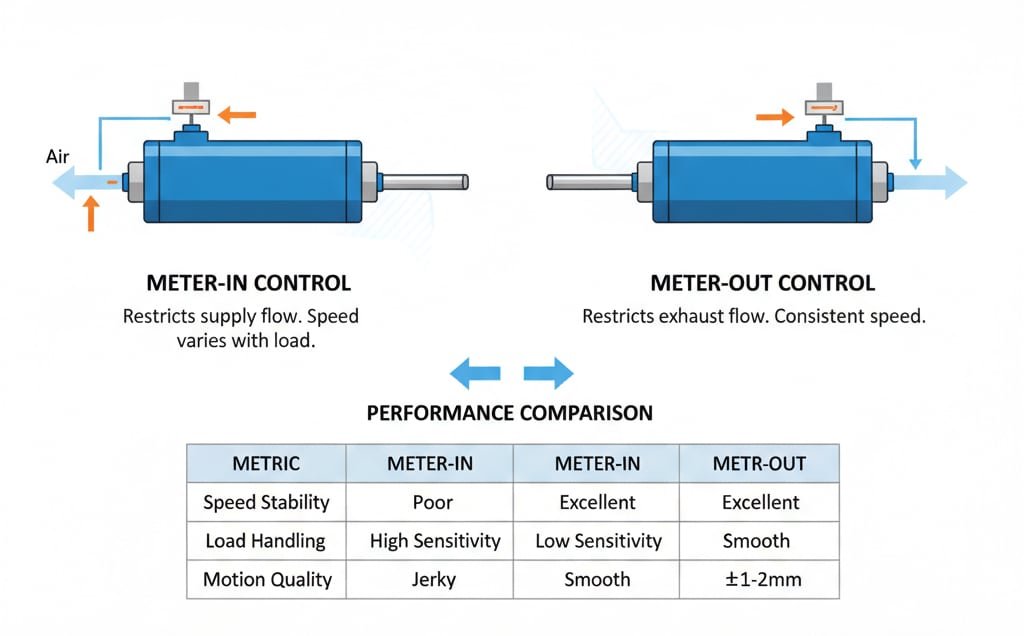

Understanding the fundamental differences between meter-in and meter-out control helps you select the optimal speed control strategy.

Meter-out circuits control exhaust flow rather than supply flow, creating consistent back-pressure that maintains steady cylinder speed regardless of load variations – this provides superior speed stability, better load handling, smoother motion, and more precise positioning compared to meter-in circuits that suffer from compressible air effects.

Flow Control Comparison

Meter-in circuits restrict incoming air flow, while meter-out circuits control exhaust flow. This fundamental difference creates dramatically different performance characteristics.

Performance Analysis

| Control Method | Speed Stability | Load Sensitivity | Motion Quality | Positioning Accuracy |

|---|---|---|---|---|

| Meter-In | Poor | High sensitivity | Jerky motion | ±5-10mm |

| Meter-Out | Excellent | Low sensitivity | Smooth motion | ±1-2mm |

| No Control | Uncontrolled | Extreme variation | Harsh impacts | ±20mm+ |

Back-Pressure Benefits

Meter-out circuits create controlled back-pressure that acts like a hydraulic dashpot2, smoothing out pressure variations and providing consistent force throughout the stroke.

Load Handling Superiority

When cylinder loads vary, meter-out circuits maintain consistent speed because the back-pressure compensates for load changes. Meter-in circuits speed up with lighter loads and slow down with heavier loads.

Air Compressibility Effects

Meter-out control minimizes the negative effects of Air compressibility3 by maintaining pressure in the working chamber, reducing the springy behavior typical of pneumatic systems.

How Do You Design Effective Meter-Out Circuits for Different Applications?

Proper circuit design ensures optimal performance while avoiding common pitfalls that reduce effectiveness and reliability.

Effective meter-out design requires selecting appropriate flow control valves sized for 150-200% of cylinder air consumption, installing exhaust silencers to handle back-pressure, using check valves4 for rapid return strokes, and calculating proper orifice sizes5 based on desired speed and cylinder specifications.

Basic Circuit Components

Essential components include precision needle valves or flow control valves, check valves for bypass, exhaust silencers rated for back-pressure, and proper fittings sized for adequate flow capacity.

Valve Sizing Calculations

Flow control valve capacity should be 150-200% of maximum cylinder air consumption to ensure adequate flow range and prevent excessive back-pressure buildup.

Circuit Configuration Options

| Configuration | Application | Advantages | Limitations |

|---|---|---|---|

| Single Direction | Extending only | Simple, cost-effective | One-way control |

| Bi-Directional | Both directions | Complete control | More complex |

| Variable Speed | Multiple speeds | Operational flexibility | Higher cost |

| Servo-Assisted | Precision control | Extreme accuracy | Complex system |

Installation Guidelines

Position flow control valves close to cylinder exhaust ports, ensure adequate exhaust silencer capacity, and provide easy access for speed adjustments during operation.

Common Design Mistakes

Avoid undersized valves, inadequate exhaust handling, missing check valves for return stroke, and improper valve placement that creates pressure drops.

Maria, a maintenance engineer from California, was experiencing erratic cylinder speeds despite installing flow controls. We discovered her meter-in setup was the problem – switching to our meter-out design immediately stabilized her process speeds! 🎯

What Are the Key Performance Benefits of Proper Meter-Out Implementation?

Well-designed meter-out circuits deliver measurable improvements in speed consistency, product quality, and operational reliability.

Meter-out circuits provide 90% better speed consistency than uncontrolled cylinders, reduce cycle time variation to under 5%, improve positioning accuracy by 80%, and enable smooth operation across varying loads – resulting in higher product quality, reduced waste, and more predictable production cycles.

Speed Consistency Improvements

Meter-out control maintains cylinder speed within ±2-5% regardless of supply pressure variations or load changes, compared to ±20-50% variation with uncontrolled systems.

Production Quality Benefits

| Metric | Uncontrolled | Meter-In | Meter-Out | Improvement |

|---|---|---|---|---|

| Cycle Time Variation | ±25% | ±15% | ±3% | 90% better |

| Positioning Accuracy | ±20mm | ±8mm | ±2mm | 90% better |

| Product Defects | 8-12% | 5-8% | 1-3% | 75% reduction |

| Equipment Wear | High impact | Moderate | Minimal | 80% reduction |

Energy Efficiency

Controlled speeds reduce unnecessary rapid cycling and allow optimization of air consumption, typically reducing compressed air usage by 15-25%.

Maintenance Benefits

Smoother operation reduces shock loads and vibration, extending cylinder life and reducing maintenance requirements. Seal life typically increases 2-3 times with proper speed control.

Process Optimization

Consistent speeds enable precise timing coordination with other equipment, improving overall line efficiency and reducing bottlenecks.

Why Should You Choose Bepto’s Engineered Speed Control Solutions?

Our complete meter-out circuit packages provide optimized performance with guaranteed compatibility and comprehensive technical support.

Bepto’s meter-out speed control systems include precision-matched components, pre-engineered circuit designs, and performance guarantees that deliver consistent 2-5% speed accuracy with plug-and-play installation – our proven solutions reduce implementation time by 75% while ensuring optimal performance for your specific application.

Complete System Approach

We provide matched component packages including properly sized flow controls, check valves, exhaust silencers, and installation hardware designed to work together optimally.

Performance Guarantees

Unlike generic components, we guarantee speed consistency and performance specifications for your specific application with comprehensive testing and validation.

Engineering Support

Our technical team provides circuit design, component selection, installation guidance, and troubleshooting support to ensure successful implementation.

Cost-Effective Solutions

| Feature | Individual Components | Bepto System | Advantage |

|---|---|---|---|

| Component Matching | Trial and error | Pre-engineered | Guaranteed compatibility |

| Installation Time | 2-4 days | 4-8 hours | 75% faster |

| Performance Risk | Unknown results | Guaranteed specs | Predictable outcome |

| Technical Support | Limited | Comprehensive | Complete solution |

| Total Cost | Higher with mistakes | Optimized pricing | Better value |

Retrofit Capability

Our meter-out systems easily retrofit to existing pneumatic cylinders and circuits, providing immediate performance improvements without major system modifications.

Quality Assurance

Every component undergoes rigorous testing and quality control to ensure reliable operation and long service life in demanding industrial applications.

Our engineered meter-out solutions transform erratic pneumatic systems into precision-controlled equipment while delivering substantial improvements in quality and efficiency. 🚀

Conclusion

Meter-out circuits provide superior speed control for pneumatic cylinders, while Bepto’s engineered solutions deliver guaranteed performance with comprehensive support and proven reliability.

FAQs About Meter-Out Speed Control Circuits

Q: Can meter-out circuits work with any pneumatic cylinder?

A: Yes, meter-out circuits are compatible with all standard pneumatic cylinders. The control is achieved through external valving, so no cylinder modifications are required for implementation.

Q: How do I determine the correct flow control valve size for my application?

A: Calculate your cylinder’s maximum air consumption (bore area × stroke × cycles per minute × 1.4) and select a flow control valve with 150-200% of that capacity to ensure adequate flow range.

Q: What’s the difference between needle valves and flow control valves for meter-out circuits?

A: Flow control valves provide more precise, repeatable adjustment and often include check valve bypass for return stroke. Needle valves are simpler but less precise and may require separate check valves.

Q: Can meter-out circuits cause cylinder stalling or jerky motion?

A: Properly designed meter-out circuits eliminate jerky motion. Stalling typically indicates undersized flow controls or excessive back-pressure. Our engineering team ensures proper sizing to prevent these issues.

Q: Why choose Bepto’s meter-out systems over assembling individual components?

A: Bepto provides pre-engineered, matched component systems with performance guarantees, comprehensive support, and 75% faster installation. This eliminates guesswork and ensures optimal results compared to trial-and-error component selection.

-

Understand the concept of back-pressure, a resistance or force opposing the desired flow of fluid through pipes, which is harnessed for control in meter-out circuits. ↩

-

Learn the operating principle of a dashpot, a mechanical device that resists motion via viscous friction, providing a damping effect. ↩

-

Explore the property of compressibility, which measures the relative volume change of a fluid or solid as a response to a pressure change. ↩

-

Discover how check valves, or one-way valves, function to allow fluid to flow through them in only one direction. ↩

-

Learn how the size of an orifice is used to control or measure the rate of fluid flow by creating a pressure drop across the plate. ↩