When your pneumatic cylinder fails to complete its stroke or moves sluggishly under load, the problem often stems from insufficient operating pressure that can’t overcome system resistance and load requirements. Calculating minimum operating pressure requires analyzing the total force requirements including load forces, friction losses, acceleration forces1, and safety factors2, then dividing by the effective piston area3 to determine the minimum pressure needed for reliable operation.

Last month, I helped David, a maintenance supervisor at a metal fabrication plant in Texas, whose press cylinders were failing to complete their forming cycles because they were operating at 60 PSI when the application actually required 85 PSI minimum pressure for reliable operation.

Table of Contents

- What Forces Must You Account for in Pressure Calculations?

- How Do You Calculate Effective Piston Area for Different Cylinder Types?

- Which Safety Factors Should You Apply to Minimum Pressure Calculations?

- How Do You Verify Calculated Pressure Requirements in Real Applications?

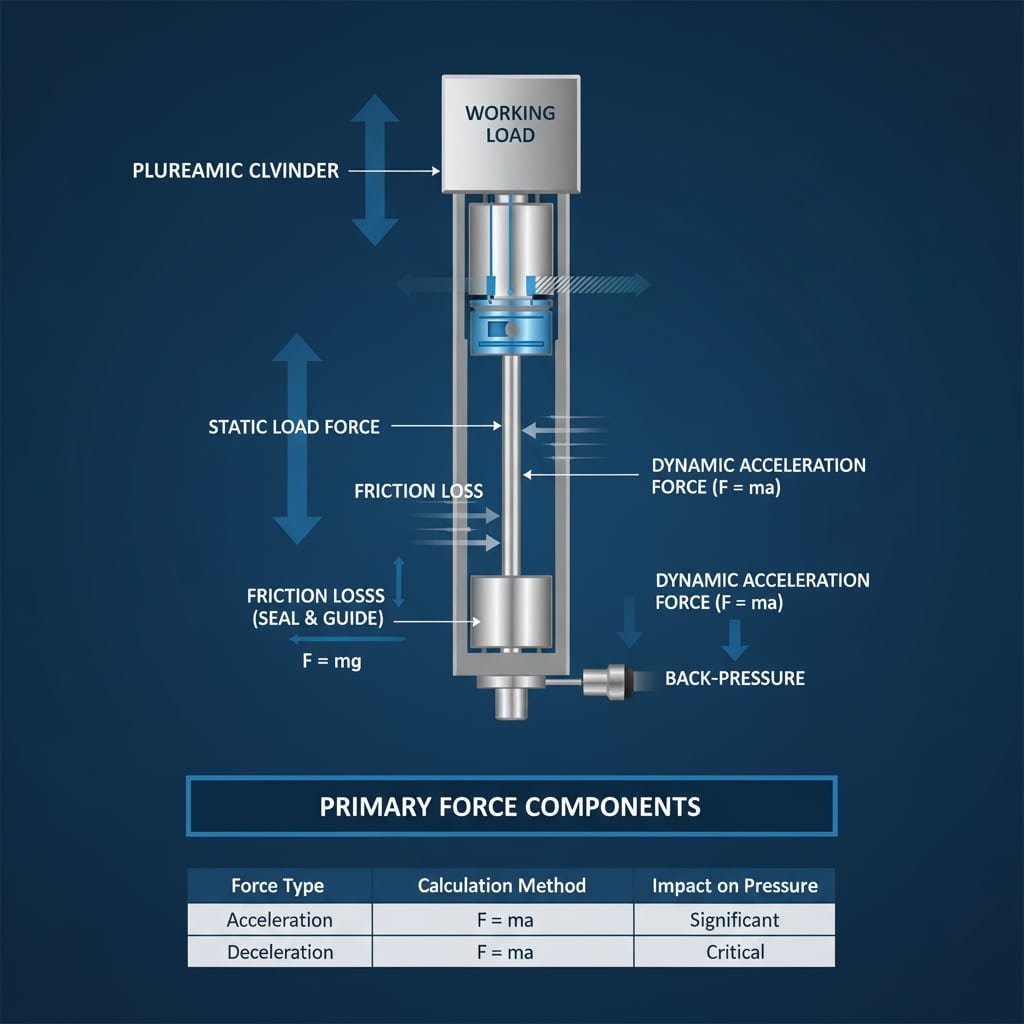

What Forces Must You Account for in Pressure Calculations? ⚡

Understanding all force components is essential for accurate minimum pressure calculations that ensure reliable cylinder operation.

Total force requirements include static load forces, dynamic acceleration forces, friction losses from seals and guides, back-pressure4 from exhaust restrictions, and gravitational forces when cylinders operate in vertical orientations, all of which must be overcome by pneumatic pressure.

Primary Force Components

Calculate these essential force elements:

Static Load Forces

- Working load – the actual force needed to perform work

- Tool weight – mass of attached tooling and fixtures

- Material resistance – forces opposing the work process

- Spring forces – return springs or counterbalancing elements

Dynamic Force Requirements

| Force Type | Calculation Method | Typical Range | Impact on Pressure |

|---|---|---|---|

| Acceleration | F = ma | 10-50% of static | Significant |

| Deceleration | F = ma (negative) | 20-80% of static | Critical |

| Inertial | F = mv²/r | Variable | Application dependent |

| Impact | F = impulse/time | Very high | Design limiting |

Friction Force Analysis

Friction significantly affects pressure requirements:

- Seal friction – typically 5-15% of cylinder force

- Guide friction – 2-10% depending on guide type

- External friction – from slides, bearings, or guides

- Stiction5 – static friction at startup (often 2x running friction)

Back-Pressure Considerations

Exhaust side pressure affects net force:

- Exhaust restrictions create back-pressure

- Flow control valves increase exhaust pressure

- Long exhaust lines cause pressure buildup

- Mufflers and filters add resistance

Gravitational Effects

Vertical cylinder orientation adds complexity:

- Extending upward – gravity opposes motion (add weight)

- Retracting downward – gravity assists motion (subtract weight)

- Horizontal operation – gravity neutral on main axis

- Angled installations – calculate force components

David’s metal fabrication plant was experiencing incomplete forming cycles because they only calculated the static forming load but ignored the significant acceleration forces needed to achieve proper forming speed, resulting in insufficient pressure for the dynamic requirements. 🔧

Environmental Force Factors

Consider these additional influences:

- Temperature effects on air density and component expansion

- Altitude effects on available atmospheric pressure

- Vibration forces from external sources

- Thermal expansion of components and materials

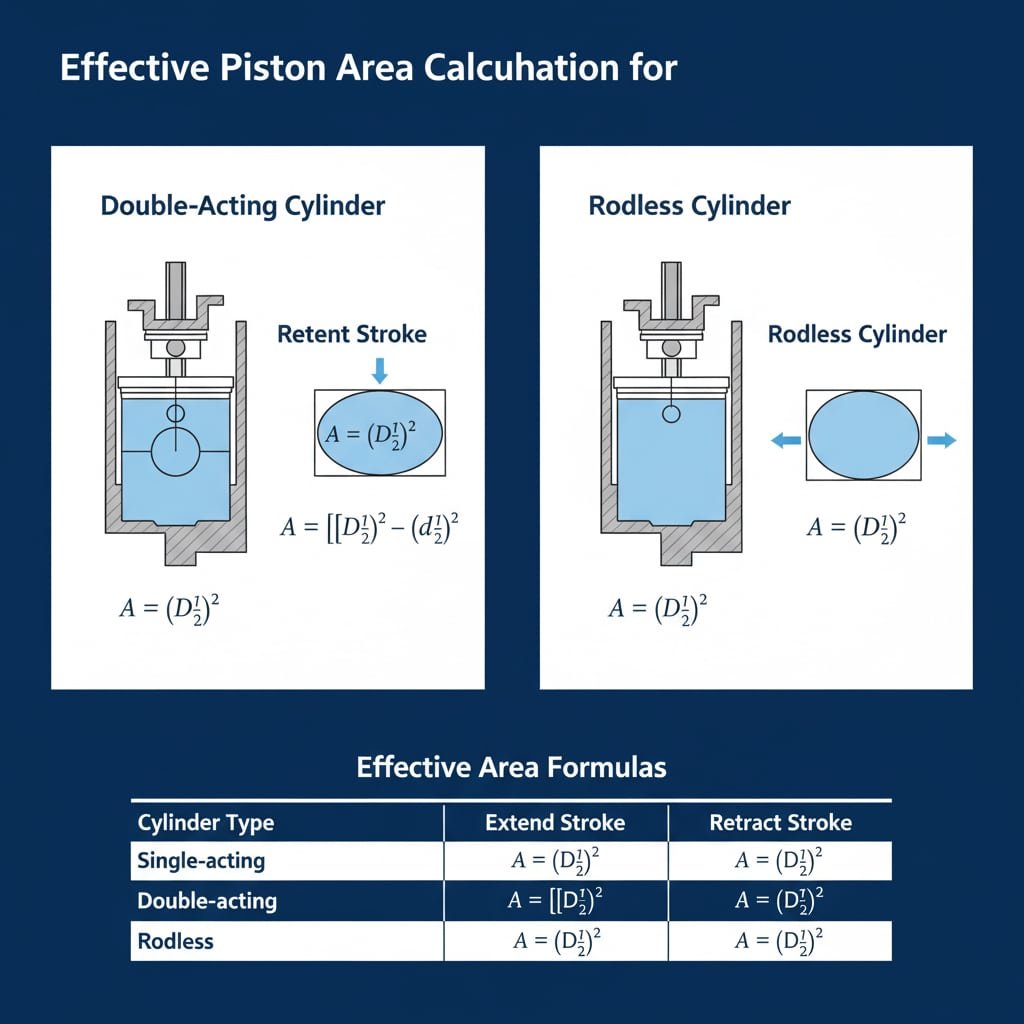

How Do You Calculate Effective Piston Area for Different Cylinder Types? 📐

Accurate piston area calculations are fundamental to determining the relationship between pressure and available force.

Calculate effective piston area using πr² for standard cylinders on the extend stroke, πr² minus rod area for retract stroke, and for rodless cylinders use the full piston area regardless of direction, accounting for seal friction and internal losses.

Standard Cylinder Area Calculations

| Cylinder Type | Extend Stroke Area | Retract Stroke Area | Formula |

|---|---|---|---|

| Single-acting | Full piston area | N/A | A = π × (D/2)² |

| Double-acting | Full piston area | Piston – rod area | A = π × [(D/2)² – (d/2)²] |

| Rodless | Full piston area | Full piston area | A = π × (D/2)² |

Where:

- D = Piston diameter

- d = Rod diameter

- A = Effective area

Area Calculation Examples

For a 4-inch bore cylinder with 1-inch rod:

Extend Stroke (Full Area)

A = π × (4/2)² = π × 4 = 12.57 square inches

Retract Stroke (Net Area)

A = π × [(4/2)² – (1/2)²] = π × [4 – 0.25] = 11.78 square inches

Force Ratio Implications

The area difference creates force imbalance:

- Extend force at 80 PSI = 12.57 × 80 = 1,006 lbs

- Retract force at 80 PSI = 11.78 × 80 = 942 lbs

- Force difference = 64 lbs (6.4% less retract force)

Rodless Cylinder Advantages

Rodless cylinders provide equal force in both directions:

- No rod area reduction on either stroke

- Consistent force output regardless of direction

- Simplified calculations for bidirectional applications

- Better force utilization of available pressure

Seal Friction Effects on Effective Area

Internal friction reduces effective force:

- Piston seals typically consume 5-10% of theoretical force

- Rod seals add 2-5% additional loss

- Guide friction contributes 2-8% depending on design

- Total friction losses often reach 10-20% of theoretical force

Bepto’s Precision Engineering

Our rodless cylinders eliminate rod area calculations while providing superior force consistency and reduced friction losses through advanced seal technology.

Which Safety Factors Should You Apply to Minimum Pressure Calculations? 🛡️

Proper safety factors ensure reliable operation under varying conditions and account for system uncertainties.

Apply safety factors of 1.25-1.5 for general industrial applications, 1.5-2.0 for critical processes, and 2.0-3.0 for safety-related functions, while considering pressure supply variations, temperature effects, and component wear over time.

Safety Factor Guidelines by Application

| Application Type | Minimum Safety Factor | Recommended Range | Justification |

|---|---|---|---|

| General industrial | 1.25 | 1.25-1.5 | Standard reliability |

| Precision positioning | 1.5 | 1.5-2.0 | Accuracy requirements |

| Safety systems | 2.0 | 2.0-3.0 | Failure consequences |

| Critical processes | 1.75 | 1.5-2.5 | Production impact |

Factors Affecting Safety Factor Selection

Consider these variables when selecting safety factors:

System Reliability Requirements

- Maintenance frequency – less frequent = higher factor

- Failure consequences – critical = higher factor

- Redundancy available – backup systems = lower factor

- Operator safety – human risk = higher factor

Environmental Variations

- Temperature fluctuations affect air density and component performance

- Pressure supply variations from compressor cycling

- Altitude changes in mobile equipment

- Humidity effects on air quality and component corrosion

Component Aging Factors

Account for performance degradation over time:

- Seal wear increases friction by 20-50% over life

- Cylinder bore wear reduces sealing effectiveness

- Valve wear affects flow characteristics

- Filter loading restricts air flow

Calculation Example with Safety Factors

For David’s forming application:

- Required forming force: 2,000 lbs

- Cylinder bore: 5 inches (19.63 sq in)

- Friction losses: 15% (300 lbs)

- Acceleration force: 400 lbs

- Total force needed: 2,700 lbs

- Safety factor: 1.5 (critical production)

- Design force: 2,700 × 1.5 = 4,050 lbs

- Minimum pressure: 4,050 ÷ 19.63 = 206 PSI

However, their system only provided 60 PSI, explaining the incomplete cycles! 📊

Dynamic Safety Considerations

Additional factors for dynamic applications:

- Acceleration variations from load changes

- Speed requirements affecting flow demands

- Cycle frequency impacts on heat generation

- Synchronization needs in multi-cylinder systems

Pressure Supply Considerations

Factor in air supply limitations:

- Compressor capacity during peak demand

- Storage tank size for intermittent high flow

- Distribution losses through piping systems

- Regulator accuracy and stability

How Do You Verify Calculated Pressure Requirements in Real Applications? 🔬

Field verification confirms theoretical calculations and identifies real-world factors that affect cylinder performance.

Verify pressure requirements through systematic testing including minimum pressure testing under full load, performance monitoring at various pressures, and measurement of actual forces using load cells or pressure transducers to validate calculations.

Systematic Testing Procedures

Implement comprehensive verification testing:

Minimum Pressure Testing Protocol

- Start at calculated minimum pressure

- Gradually reduce pressure until performance degrades

- Note failure point and failure mode

- Add 25% margin above failure point

- Verify consistent operation over multiple cycles

Performance Verification Matrix

| Test Parameter | Measurement Method | Acceptance Criteria | Documentation |

|---|---|---|---|

| Stroke completion | Position sensors | 100% of rated stroke | Pass/fail record |

| Cycle time | Timer/counter | Within ±10% of target | Time log |

| Force output | Load cell | ≥95% of calculated | Force curves |

| Pressure stability | Pressure gauge | ±2% variation | Pressure log |

Real-World Testing Equipment

Essential tools for field verification:

- Calibrated pressure gauges (±1% accuracy minimum)

- Load cells for direct force measurement

- Flow meters to verify air consumption

- Temperature sensors for environmental monitoring

- Data loggers for continuous monitoring

Load Testing Procedures

Verify performance under actual working conditions:

Static Load Testing

- Apply full working load to cylinder

- Measure minimum pressure for load support

- Verify holding capability over time

- Check for pressure decay indicating leakage

Dynamic Load Testing

- Test at normal operating speed and acceleration

- Measure pressure during acceleration phases

- Verify performance at maximum cycle rates

- Monitor pressure stability during continuous operation

Environmental Testing

Test under actual operating conditions:

- Temperature extremes expected in service

- Pressure supply variations from compressor cycling

- Vibration effects from nearby equipment

- Contamination levels in actual air supply

Performance Optimization

Use test results to optimize system performance:

- Adjust pressure settings based on actual requirements

- Modify safety factors based on measured variations

- Optimize flow controls for best performance

- Document final settings for maintenance reference

After implementing our systematic testing approach, David’s facility determined they needed 85 PSI minimum pressure and upgraded their air system accordingly, eliminating the incomplete forming cycles and improving production efficiency by 23%. 🎯

Bepto’s Application Support

We provide comprehensive testing and verification services:

- On-site pressure analysis and optimization

- Custom test procedures for specific applications

- Performance validation of cylinder systems

- Documentation packages for quality systems

Conclusion

Accurate minimum pressure calculations combined with proper safety factors and field verification ensure reliable cylinder operation while avoiding oversized air systems and unnecessary energy costs. 🚀

FAQs About Cylinder Pressure Calculations

Q: Why do my cylinders work fine at higher pressures but fail at the calculated minimum?

Calculated minimums often don’t account for all real-world factors like seal stiction, temperature effects, or dynamic loads. Always add appropriate safety factors and verify performance through actual testing under operating conditions rather than relying solely on theoretical calculations.

Q: How does temperature affect minimum pressure requirements?

Cold temperatures increase air density (requiring less pressure for same force) but also increase seal friction and component stiffness. Hot temperatures decrease air density (requiring more pressure) but reduce friction. Plan for worst-case temperature conditions in your calculations.

Q: Should I calculate pressure based on extend or retract stroke requirements?

Calculate for both strokes since rod area reduction affects retract force. Use the higher pressure requirement as your minimum system pressure, or consider rodless cylinders that provide equal force in both directions for simplified calculations.

Q: What’s the difference between minimum operating pressure and recommended operating pressure?

Minimum operating pressure is the theoretical lowest pressure for basic function, while recommended operating pressure includes safety factors for reliable operation. Always operate at recommended pressure levels to ensure consistent performance and component longevity.

Q: How often should I recalculate pressure requirements for existing systems?

Recalculate annually or whenever you modify loads, speeds, or operating conditions. Component wear over time increases friction losses, so systems may need higher pressure as they age. Monitor performance trends to identify when pressure increases are needed.

-

Understand how to calculate the force required for acceleration using Newton’s Second Law. ↩

-

Explore the definition and importance of using a Factor of Safety (FoS) in engineering design. ↩

-

A guide on how to calculate the effective area of a piston, accounting for the piston rod. ↩

-

Learn how back-pressure is created in pneumatic circuits and how it affects system force. ↩

-

Understand the engineering concept of ‘stiction’ (static friction) and how it affects initial movement. ↩