Your pneumatic cylinder is stuttering, your cycle times are inconsistent, and production quality is suffering. You’ve adjusted pressures, checked seals, and replaced fittings—but the erratic motion persists. The problem might not be your cylinder at all; it could be that you’re using the wrong speed control method for your application.

Meter-in speed control1 restricts airflow entering the cylinder to regulate extension/retraction speed, while meter-out restricts exhaust airflow leaving the cylinder. Meter-out provides superior load control and smooth motion under varying loads, making it the preferred method for most industrial applications, whereas meter-in works best for light-load, gravity-assisted movements where precise positioning isn’t critical.

Last month, I worked with Marcus, a production engineer at an automotive parts manufacturer in Michigan, who was battling inconsistent cycle times on a vertical assembly station. His team had been using meter-in control for three years, constantly adjusting flow controls to compensate for load variations. Within two days of switching to meter-out configuration with our Bepto flow control valves, his cycle time variation dropped from ±0.8 seconds to ±0.1 seconds—transforming a bottleneck into a reliable process. 🎯

Table of Contents

- What Is the Fundamental Difference Between Meter-In and Meter-Out Control?

- When Should You Use Meter-Out vs. Meter-In Speed Control?

- How Do Load Conditions Affect Speed Control Method Selection?

- What Are the Best Practices for Implementing Pneumatic Speed Control?

What Is the Fundamental Difference Between Meter-In and Meter-Out Control?

Understanding the physics behind these two methods is essential for anyone designing or troubleshooting pneumatic systems—the difference goes far beyond just valve placement. 🔧

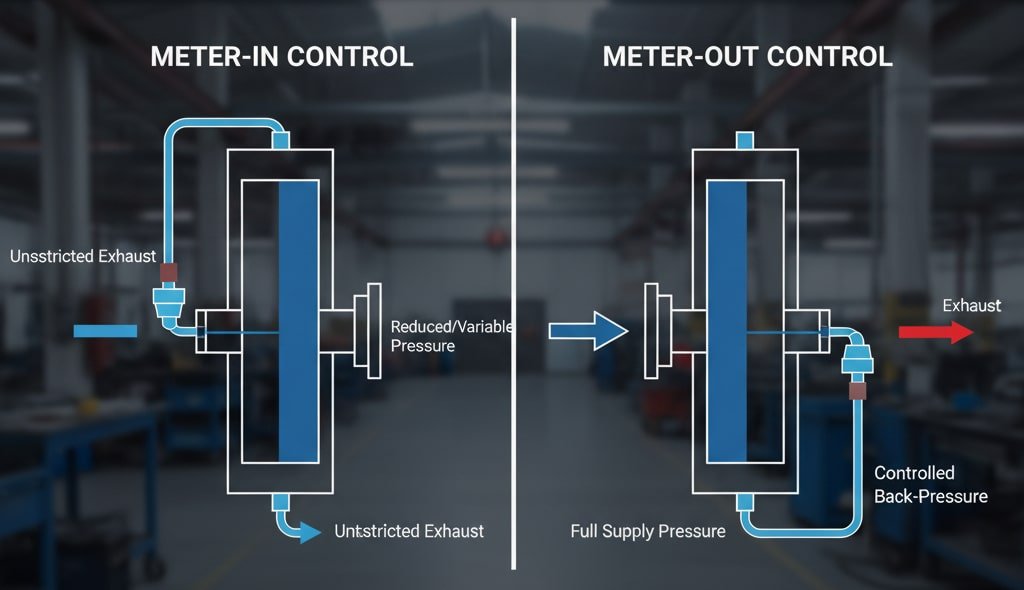

Meter-in control throttles compressed air before it enters the cylinder chamber, creating a pressure differential that slows piston movement, while meter-out control allows full pressure into the cylinder but restricts exhaust flow, creating back-pressure2 that provides controlled resistance against the moving load. This fundamental difference in pressure dynamics determines stability, controllability, and application suitability.

Meter-In Control Mechanics

In meter-in configuration, the flow control valve is installed on the supply port of the cylinder. As air enters through the restricted orifice:

- Pressure builds gradually in the extending chamber

- The cylinder receives reduced pressure compared to supply line

- Piston acceleration depends on incoming flow rate

- Exhaust air exits unrestricted through the opposite port

This creates a “starved” condition where the cylinder can only move as fast as air can enter through the restriction.

Meter-Out Control Mechanics

With meter-out configuration, the flow control valve is placed on the exhaust port:

- Full supply pressure enters the extending chamber immediately

- A cushion of trapped air forms in the retracting chamber

- This back-pressure creates controlled resistance

- The piston can only advance as fast as exhaust air can escape

Think of it like controlling a car’s speed: meter-in is like limiting fuel to the engine, while meter-out is like applying the brakes—one starves power, the other provides controlled resistance.

Visual Comparison

| Aspect | Meter-In | Meter-Out |

|---|---|---|

| Flow Control Location | Supply port (inlet) | Exhaust port (outlet) |

| Extending Chamber Pressure | Reduced/Variable | Full supply pressure |

| Retracting Chamber Pressure | Atmospheric (vented) | Elevated (back-pressure) |

| Control Mechanism | Pressure starvation | Controlled resistance |

| Energy Efficiency | Lower (wasted pressure drop) | Higher (uses full pressure) |

At Bepto, we manufacture both meter-in and meter-out flow control valves, but we recommend meter-out for approximately 85% of applications based on our technical analysis and field experience across thousands of installations worldwide. 📊

When Should You Use Meter-Out vs. Meter-In Speed Control?

Choosing the wrong speed control method can lead to jerky motion, premature component wear, and frustrated maintenance teams—but the selection criteria are actually quite straightforward once you understand the principles.

Use meter-out control for vertical loads, variable loads, precision positioning, and any application requiring smooth consistent motion, as the back-pressure provides inherent damping and load resistance. Reserve meter-in control for horizontal light-load applications, gravity-assisted movements, or situations where you specifically need rapid initial acceleration with gradual deceleration.

Meter-Out: The Industrial Standard

Ideal Applications:

- Vertical lifting operations (fighting gravity)

- Variable or unpredictable loads (changing workpiece weights)

- Precision positioning tasks (assembly, testing)

- Pushing operations (pressing, stamping)

- Any application requiring smooth motion under load

Why It Works Better:

The back-pressure created in the exhaust chamber acts as a pneumatic shock absorber, preventing the load from “running away” and causing jerky motion. This is especially critical when the load assists cylinder movement (like lowering a weight).

Real-World Success Story:

Jennifer, a packaging line manager at a food processing facility in Wisconsin, was experiencing product damage from inconsistent cylinder speeds on a vertical stacking application. Her OEM supplier suggested replacing the entire cylinder assembly at $3,200. Instead, we analyzed her system and identified that her team had inadvertently installed flow controls in meter-in configuration during a maintenance procedure.

We supplied properly rated Bepto meter-out flow control valves ($180 total investment) and provided installation guidance. Within one hour, her line was running smoothly with zero product damage—a 95% cost savings compared to the OEM recommendation. 💰

Meter-In: Specialized Applications

Appropriate Uses:

- Horizontal movements with light loads (no gravity component)

- Gravity-assisted lowering where you want controlled descent

- Applications requiring fast initial acceleration

- Simple on/off movements without precision requirements

- Cost-sensitive applications with minimal performance demands

Limitations to Consider:

- Poor load holding capability

- Susceptible to speed variations with load changes

- Can cause jerky or unstable motion

- Reduced force output (operating on reduced pressure)

- Potential for “runaway” conditions with assisting loads

Decision Matrix

| Your Application Characteristics | Recommended Method |

|---|---|

| Vertical cylinder orientation | Meter-Out ✅ |

| Horizontal with heavy/variable loads | Meter-Out ✅ |

| Precision positioning required | Meter-Out ✅ |

| Smooth motion critical | Meter-Out ✅ |

| Horizontal with consistent light load | Either method acceptable |

| Gravity-assisted lowering only | Meter-In (sometimes) |

| Absolute lowest cost, basic function | Meter-In |

When in doubt, choose meter-out—it’s the safer, more versatile option that will handle unexpected conditions better. Our technical team can review your specific application and provide recommendations within 24 hours. 🚀

How Do Load Conditions Affect Speed Control Method Selection?

Load characteristics are the single most important factor in speed control method selection—yet they’re often overlooked during system design, leading to performance issues that plague operations for years.

Variable loads, assisting loads3 (gravity or external forces pushing with the cylinder), and high-inertia loads all require meter-out control to maintain stable motion, while meter-in control becomes increasingly unstable as load variability increases because it cannot provide the back-pressure resistance needed to counteract load-induced acceleration. Understanding your load profile is essential for reliable pneumatic system performance.

Load Classification and Control Impact

Resisting Loads (Opposing Cylinder Motion)

These loads work against the cylinder’s direction of travel:

- Examples: Horizontal pushing, lifting, compressing springs

- Meter-In Performance: Acceptable for light, consistent loads

- Meter-Out Performance: Excellent—provides smooth, controlled motion

- Key Consideration: Load magnitude and consistency

Assisting Loads (Helping Cylinder Motion)

These loads push in the same direction as cylinder movement:

- Examples: Vertical lowering, gravity-fed systems, spring return assist

- Meter-In Performance: Poor to dangerous—can cause runaway motion

- Meter-Out Performance: Essential—back-pressure prevents runaway

- Key Consideration: Safety and motion control

Variable Loads (Changing During Cycle)

Load magnitude changes during operation:

- Examples: Picking varying product sizes, multi-stage operations

- Meter-In Performance: Very poor—speed varies with load changes

- Meter-Out Performance: Good—back-pressure adapts to load variations

- Key Consideration: Consistency requirements

Technical Analysis: Pressure Dynamics Under Load

Let’s examine what happens with a 50mm bore cylinder at 6 bar supply pressure handling a 500N variable load (±200N variation):

| Condition | Meter-In Behavior | Meter-Out Behavior |

|---|---|---|

| Light Load (300N) | Faster speed, reduced control | Consistent speed maintained |

| Nominal Load (500N) | Design speed achieved | Consistent speed maintained |

| Heavy Load (700N) | Slower speed, possible stalling | Slight speed reduction, stable |

| Speed Variation | ±40-60% | ±5-10% |

| Motion Quality | Jerky, unpredictable | Smooth, controlled |

Case Study: Solving a Chronic Speed Control Problem

Robert, a maintenance supervisor at a metal fabrication shop in Ohio, contacted us after struggling with a parts transfer system for eight months. His vertical rodless cylinder4 application was experiencing:

- Inconsistent cycle times (2.1 to 3.8 seconds for the same movement)

- Occasional “slam down” events when loads were lighter

- Premature wear on guide rails and mounting hardware

His system used meter-in control with premium OEM components. After reviewing his application details, I immediately identified the issue: his load varied from 15kg to 45kg depending on part configuration, and the vertical orientation created an assisting load condition during lowering.

We supplied him with:

- Bepto meter-out flow control valves (properly sized for his flow requirements)

- Quick-exhaust valves for the return stroke

- Technical documentation for proper installation

Results after implementation:

- Cycle time variation reduced to ±0.2 seconds ✅

- Complete elimination of slam-down events ✅

- Smooth, controlled motion regardless of load weight ✅

- Total investment: $340 (versus $12,000 for the cylinder replacement his OEM suggested)

The key lesson? The right control method matters more than premium component brands. 💡

Sizing Considerations for Load Conditions

When implementing meter-out control for varying loads:

- Calculate maximum exhaust flow based on cylinder volume and desired cycle time

- Size flow control valve for 20-30% above calculated flow (provides adjustment range)

- Consider pilot-operated check valves5 for vertical applications to prevent drift

- Install pressure gauges during commissioning to verify back-pressure levels (typically 1-2 bar)

Our engineering team can perform these calculations for your specific application—just provide cylinder specifications and load details through our website contact form.

What Are the Best Practices for Implementing Pneumatic Speed Control?

Even with the correct control method selected, improper implementation can undermine performance—these field-proven practices will help you achieve optimal results from your pneumatic speed control system. ⚙️

Install flow controls as close as possible to the cylinder ports, use properly sized fittings to minimize pressure drop, implement symmetrical control on both extend and retract strokes when needed, and always include pressure gauges during commissioning to verify system behavior. Additionally, consider quick-exhaust valves on the unrestricted port to maximize speed on the return stroke and improve overall cycle efficiency.

Installation Best Practices

Flow Control Valve Placement

- Mount directly on cylinder ports when possible (minimizes dead volume)

- Use short, large-bore tubing if remote mounting is necessary

- Orient adjustment knobs for easy access during commissioning

- Label clearly (extend/retract, meter-in/meter-out) for future maintenance

Complementary Components

Quick-Exhaust Valves:

Install on the unrestricted port to vent exhaust air directly to atmosphere rather than back through the valve manifold:

- Increases return stroke speed by 30-50%

- Reduces cycle time without compromising controlled stroke

- Particularly valuable for rodless cylinders with large bore sizes

Pilot-Operated Check Valves:

For vertical applications, add check valves to prevent load drift:

- Holds position when air pressure is lost

- Prevents slow creep under sustained loads

- Essential for safety in lifting applications

Commissioning Procedure

Follow this systematic approach for optimal results:

- Start with flow controls fully open (minimum restriction)

- Gradually close the control until desired speed is achieved

- Test with minimum and maximum expected loads to verify consistency

- Monitor back-pressure (should be 1-2 bar for meter-out)

- Check for smooth acceleration and deceleration

- Document final settings for future reference

Common Implementation Mistakes to Avoid

| Mistake | Consequence | Solution |

|---|---|---|

| Undersized flow control valve | Insufficient flow even when fully open | Use Cv calculation or consult manufacturer |

| Excessive tubing length | Pressure drop, sluggish response | Minimize distance, increase tube diameter |

| Mixed meter-in/meter-out | Unpredictable behavior | Use consistent method on both strokes |

| No adjustment documentation | Settings lost during maintenance | Label and record all adjustments |

| Ignoring air quality | Valve clogging, erratic control | Ensure proper filtration (40 micron max) |

Bepto’s Technical Support Advantage

When you source pneumatic components from us, you’re not just buying valves and cylinders—you’re gaining access to decades of application engineering experience. We provide:

- Pre-sale application review to confirm proper component selection

- Detailed installation drawings specific to your configuration

- Commissioning checklists to ensure optimal setup

- Troubleshooting guides for common issues

- Direct engineer access via phone or email for complex situations

A pharmaceutical equipment manufacturer in New Jersey recently told me that our technical documentation saved their commissioning team 12 hours compared to their previous OEM supplier who provided only generic manuals. Time is money, and we respect both. ⏱️

Optimization for Rodless Cylinders

Rodless cylinders present unique speed control considerations due to their design:

- Higher exhaust volumes (both piston sides vent during movement)

- Longer stroke lengths (often 1-3 meters)

- External load mounting (different force dynamics)

For rodless cylinder applications, we typically recommend:

- Larger flow control valves (one size up from standard cylinder calculation)

- Meter-out control on both directions for bidirectional load control

- Dual pressure regulation for extend/retract if force requirements differ significantly

Our Bepto rodless cylinders come with application-specific speed control recommendations based on your stroke length and load profile—just another way we make pneumatic system design easier for our customers. 🎯

Conclusion

Selecting between meter-in and meter-out speed control isn’t just a technical detail—it’s a fundamental decision that determines whether your pneumatic system will perform reliably or become a constant source of frustration, and in most industrial applications, meter-out control delivers the stability, consistency, and load-handling capability that modern manufacturing demands.

FAQs About Pneumatic Speed Control Methods

Q: Can I use meter-in and meter-out control on the same cylinder for different strokes?

Yes, this is actually quite common and often optimal—for example, using meter-out control on the working stroke (where load control is critical) and meter-in or unrestricted flow on the return stroke (where speed is less critical). Many of our customers implement this asymmetric control strategy to optimize both cycle time and motion quality. Just ensure each stroke has the appropriate control method for its specific load conditions.

Q: Why does my cylinder speed change even with flow controls installed?

Speed variations typically indicate either incorrect control method selection (meter-in with variable loads), insufficient supply pressure, air supply flow limitations, or contamination in the flow control valve. First verify you’re using meter-out control for load-bearing applications, then check that supply pressure remains stable under load (minimum 5-6 bar recommended), and finally inspect/clean or replace the flow control valve if contamination is suspected.

Q: How do I calculate the correct flow control valve size for my application?

Calculate required flow using the formula: Q = (A × S × 60) / t, where Q is flow in liters/min, A is piston area in cm², S is stroke in cm, and t is desired time in seconds. Then multiply by 1.3 for safety margin and select a valve with Cv rating that provides this flow at your operating pressure differential. Our technical team can perform these calculations for you—just send us your cylinder specifications and desired cycle time.

Q: Will meter-out control damage my cylinder by creating excessive back-pressure?

No, properly implemented meter-out control is completely safe and actually reduces cylinder wear by providing smoother, more controlled motion. The back-pressure created (typically 1-2 bar) is well within the design limits of standard industrial cylinders. In fact, the jerky motion and shock loads from improper meter-in control cause far more wear than the controlled resistance of meter-out configuration.

Q: Can I retrofit my existing meter-in system to meter-out without replacing components?

In most cases, yes—you simply need to relocate the flow control valves from the supply ports to the exhaust ports, which usually requires only replumbing the pneumatic connections. The same flow control valves can typically be reused. However, verify that your valve manifold or directional control valve has adequate exhaust port capacity. We can review your existing system layout and provide retrofit guidance—many customers have successfully converted systems in under an hour with dramatic performance improvements.

-

Learn the fundamental principles of meter-in flow control circuits. ↩

-

Understand the role of back-pressure in pneumatic circuits and how it provides control. ↩

-

See a technical explanation of how assisting (or overrunning) loads affect cylinder motion. ↩

-

Explore the design and common applications of rodless cylinders in automation. ↩

-

Get a clear definition of pilot-operated check valves and their function in pneumatic systems. ↩